。

2. The length is infinitely extended. For crushing, the feeding design is the key.

3. The speed is different, its speed changes with the change of the host, and the design method of the traction changes accordingly

4. The width is different. For the crusher cavity, this is one of the important parameters for selecting the size of the machine.

5. The thickness varies, any design is limited to a certain value, and the thinnest and thickest are all within this range.

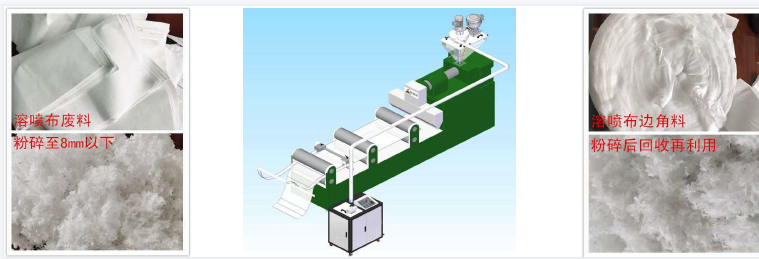

Features of Meltblown Cloth Crusher:

Traction part: [multiple ways of unique design]

The traction spindle is precision machined with high-strength seamless steel pipe, and then plated with hard chrome, which is beautiful, never rusted, durable and environmentally friendly.

The body is made of national standard steel, which is beautiful and durable.

The power part adopts the gear reduction motor of the famous brand manufacturer, with a new integrated design, which is convenient, lightweight, sturdy and durable.

And equipped with inverters from famous brand manufacturers, which can be used synchronously with the host, the speed can meet the needs of different customers, and the quality is stable.

Feeding fan part:【Various structures for easy collection】

The base of the feeding fan is welded by the national standard angle iron. At the same time, the motor from famous brand manufacturers is adopted, which is of stable quality and durable.

The fan shell and blades are made of stainless steel, which is beautiful, never rusted, environmentally friendly and hygienic, and durable.

The unique fan blade design increases the wind pressure, and has strong material conveying ability and stable operation.

shredder part:【A variety of tool holders, optional special materials】

刀具The knives are made of special steel from famous brand manufacturers, with high hardness, good toughness, strong wear resistance, especially strong and durable, easy to crush various soft and hard materials, and strong crushing ability.

This machine adopts extremely wear-resistant high-quality alloy cutting tools to crush the material at normal temperature without changing its chemical composition.

The body is made of high-quality steel plate welded and processed, which is strong and durable, and will never burst.

The frame is welded by national standard channel steel, and is equipped with screw fixing device to maintain the stability of the machine.

The tool holder adopts a hollow structure design, which is stable in operation, small in wind resistance, fast in heat dissipation, and durable.

The bearing adopts the bearing of the famous brand manufacturer, which is stable and durable. The flywheel and pulley are finely cast and precisely machined, so they are sturdy and durable.

The thickness of the pulverized raw material ranges from 0.5 to 3 mm. [If other thickness materials, please specify when ordering].

Simple operation, reliable performance, low noise and high quality.

Adopt synchronous belt drive mode, mature technology and stable operation.

Business hotline: Miss Liu 13776319563

Technical support: Gu Gong 18913224469

e-mail address:gooaon@163.com

Ali Wangpu:https://www.gooaon.com.cn

Address: No. 56, Gangpu East Road, Zhangpu Town, Kunshan City, Suzhou, Jiangsu Province

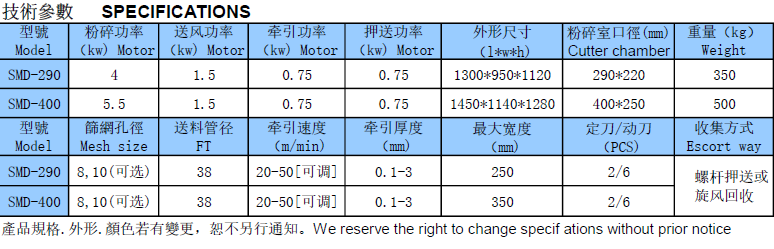

Product selection

technical support