。

Gu'an central feeding system adopts industrial computer to automatically centrally control all machines, and realizes 24-hour continuous feeding operation for all material units. With the special functions of each machine in the system, it can perfectly realize the mixing and dehumidification of raw materials. , drying, conveying, metering and other special requirements. The central feeding system has a variety of monitoring and protection functions, and the work is safe and reliable, which is the core premise for enterprises to realize unmanned chemical plants.

Gu'an central centralized feeding system

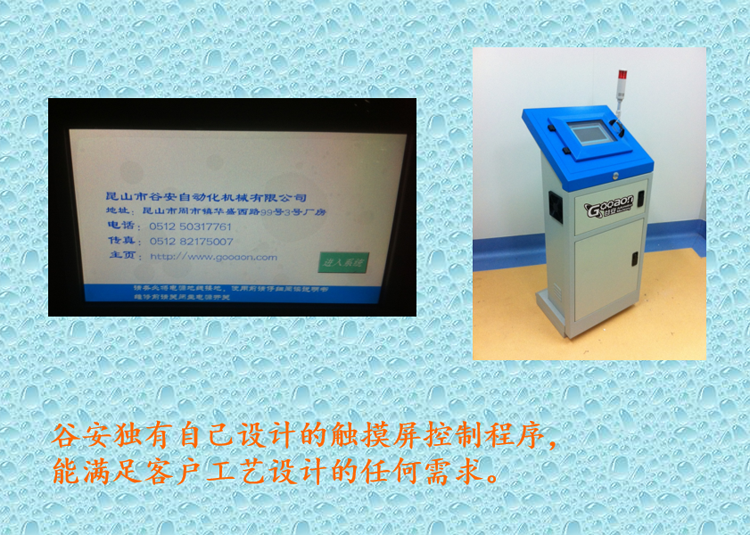

Control and Power

The control components of Gu'an central control system adopt German Siemens brand PLC and Siemens color touch screen, the control is stable and reliable, and it is convenient for later expansion. All control accessories adopt international famous brands to ensure the stability and reliability of the system. Roots blower or double-stage high-pressure blower is selected for the conveying power according to the actual situation of the site to ensure sufficient conveying power and no material accumulation in the pipeline.

storage and delivery

Whether small storage tanks or large outdoor storage bins, we can provide you with the most suitable storage solution to save space, protect raw materials and reduce transportation costs. The parts in contact with the raw materials are made of stainless steel and the filter device of the conveying system effectively ensures that the raw materials are not polluted during the conveying process. The flexible conveying air supply adjustment system can effectively avoid the situation of wire drawing or dust caused by different conveying conditions by adjusting the conveying speed. The closed cycle secondary conveying system can greatly reduce the heat loss during the conveying process and the risk of re-absorbing moisture of the dried raw materials during the conveying process of the hot material and the heat preservation hopper that needs to be sent to the molding machine after drying.

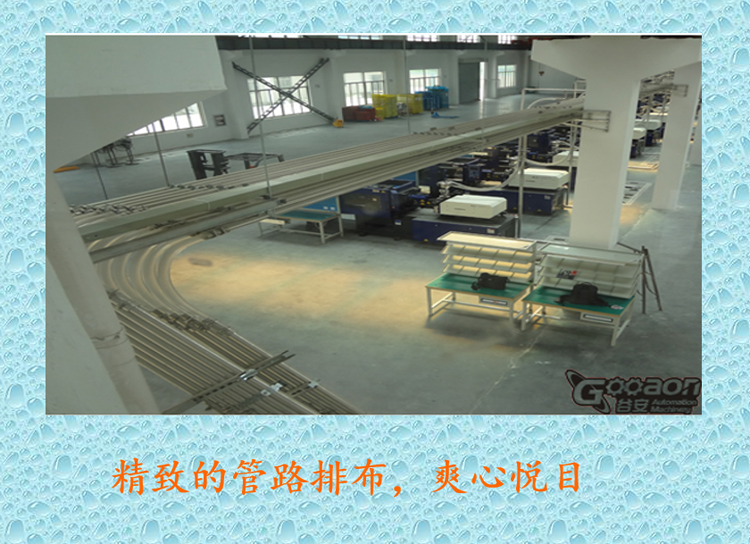

Raw material distribution

The standard manual raw material distribution station uses quick couplings to allow you to choose the best batching line, and the central distributor and its matching couplings can improve the efficiency of the system. The automatic raw material distribution station is controlled by a central console, which can be used in the occasion of large-scale feeding system.

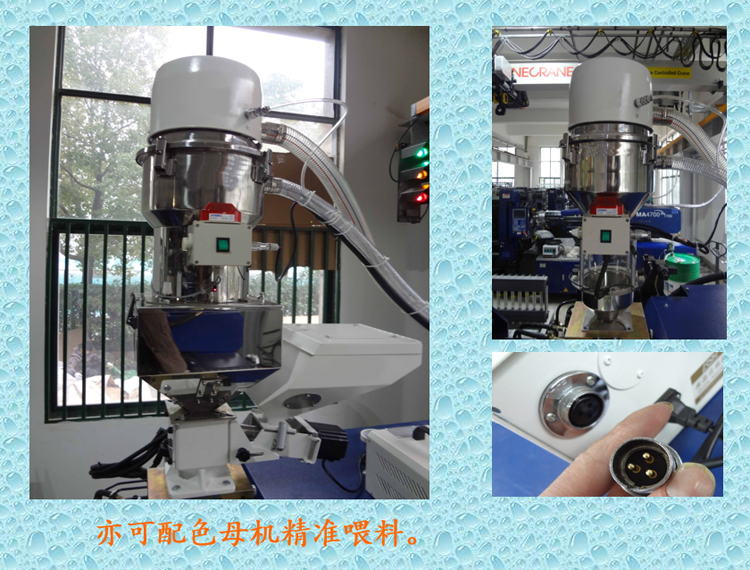

metering mix

Gu'an volumetric color masterbatch machine can be used for the metering of color masterbatch raw materials, and the production range is 0.2~32kg/hr. If the customer has higher requirements for the addition ratio and accuracy of the color masterbatch, we recommend using a weighing-type color masterbatch machine, which adopts the weighing measurement method, and the production range is 0.04~32kg/hr.

In the plastic molding process, drying becomes a particularly critical stage. It must be ensured that the moisture in the raw materials is removed and the drying temperature is reasonable. Gu'an's dehumidifying dryer can provide dry air with a dew point of -40°C or lower, and can monitor various parameters in a timely manner and ensure a constant dew point.

Dew point setting and intelligent regeneration function, the dew point temperature of traditional dehumidifiers cannot be set, and dehumidifiers are working at the maximum load state. However, when processing raw materials with high humidity requirements, the dew point must be set and controlled. The setting of dew point temperature is related to the control of regenerative energy, which reduces energy consumption compared to traditional dehumidifiers.

Extrusion Control

For plastic film blowing machinery, the air ring is an important component of film bubble forming and cooling. The air ring has a great influence on the film thickness uniformity and film output. Shibo chiller is specially designed for extruder air ring cooling, with precise temperature control, energy saving and durability.

Business hotline: Miss Liu 13776319563

Technical support: Gu Gong 18913224469

e-mail address:gooaon@163.com

Ali Wangpu:https://www.gooaon.com.cn

Address: No. 56, Gangpu East Road, Zhangpu Town, Kunshan City, Suzhou, Jiangsu Province

Product selection

technical support