。

As China's rubber and plastic auxiliary equipment industry, Gu'an Machinery can plan for you from the auxiliary equipment of the entire plastic molding plant. The technical and R&D team can tailor-made for customers according to the site and actual needs, and plan a complete set of flexible, effective and accurate Reliable automated production system solutions. Beautify the workshop to enhance the corporate image, optimize the production process, improve production efficiency and product quality, reduce operating costs, enhance competition, and help customers stand out. The planning and solutions provided by the service team.

Central centralized feeding system, injection molding workshop central feeding system

一、working principle

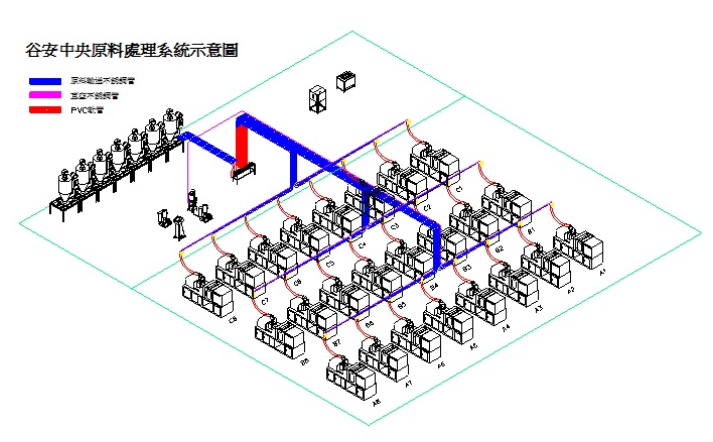

The central feeding system is composed of central vacuum fan, central dust filter, vacuum hopper, raw material storage equipment, and corresponding dehumidification and drying equipment, color matching equipment and crushing and recycling device. Relying on the central micro-processing control and monitoring system, the raw materials are automatically transported to multiple corresponding plastic molding hosts for use.

二、Product Features:

1.A variety of raw materials can be automatically supplied to multiple hosts to meet the needs of 24-hour non-stop production.

2.Energy saving --- Only a few people can control the common material requirements of the whole plant, reduce labor, reduce many single equipment, improve space utilization, save electricity and maintenance costs.

3.Personalization - Different customers, different workshop characteristics, and different raw material usage requirements can design optimized solutions according to actual needs.

4.The image of the current chemical factory - will reduce the pollution of raw materials and dust to the injection molding production area to a minimum, so as to maintain a clean production workshop and reduce noise, and finally realize an unmanned automated production workshop and establish a modernized Factory management image.

Business hotline: Miss Liu 13776319563

Technical support: Gu Gong 18913224469

e-mail address:gooaon@163.com

Ali Wangpu:https://www.gooaon.com.cn

Address: No. 56, Gangpu East Road, Zhangpu Town, Kunshan City, Suzhou, Jiangsu Province

Product selection

technical support