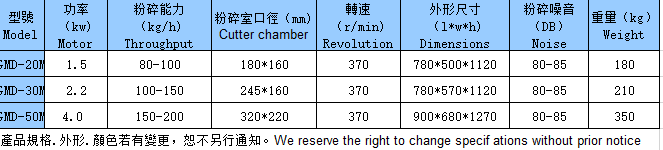

二、product description

The machine-side medium-speed pulverizer is placed on the side of the injection molding machine to pulverize and recycle the nozzle material, which greatly reduces the production cost. At the same time, the nozzle material and leftover material are recycled and reused to achieve environmental protection; Manual operation, while saving labor costs.

三、Use of the product

The machine side medium speed pulverizer is suitable for the recycling of various plastic materials, including plastic scraps, recycled materials, and semi-finished products. It is suitable for soft chlorine, polycarbon, nylon, ABS and other soft and hard sheet plastics. , mesh plastic. The machine has compact structure, beautiful appearance and convenient operation. The optimized design of the rotating knife minimizes the energy consumption and increases the cutting efficiency.

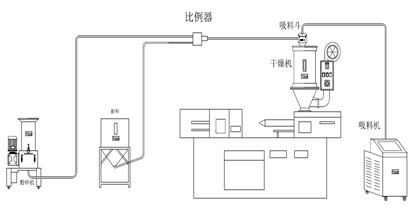

四、product recycling system

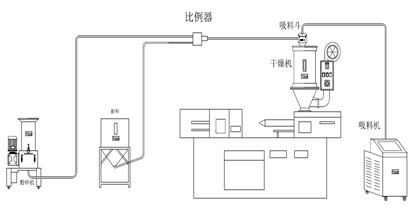

Optional automatic recycling system or powder separation system can fully avoid the waste of manpower and materials, so as to achieve the best recycling effect.

Time-saving: Recycle immediately within 30 seconds, without waiting for centralized crushing, and it is clean and clean;

Improve quality: Nozzle material will be oxidized and humidified (absorbing water) after being taken out at high temperature, and its physical properties will be destroyed. Immediate recovery within 30 seconds can reduce physical strength and reduce the damage of color and gloss;

Save money: Recycling in a short time, avoiding pollution, and the defective rate caused by mixing materials, can reduce the waste and loss of plastic, labor, management, storage, and purchasing funds;

Wide range of uses: suitable for crushing and recycling PU, PVC, PC, ABC and other soft and hard material nozzle materials;

Simple: easy-to-remove design, easy to change color and material, compact and occupy less space, suitable for use next to the machine in a small workshop;

Adopt medium speed motor, low noise and low energy consumption;

Adopt stainless steel feeding hopper design, easy to clean and do not pollute raw materials;

The motor is equipped with an overload protection device and a power supply chain protection system, which is safe and reliable for operation and cleaning;

五、Product performance

1、 The medium-speed machine-side pulverizer is mainly used to be placed next to the plastic molding machine and matched with the manipulator to pulverize the nozzle material into granules, and then the immediate recycling device will send it back to the plastic molding machine for recycling again.

2. Because of the low speed of this type of model, the noise generated during use is low.

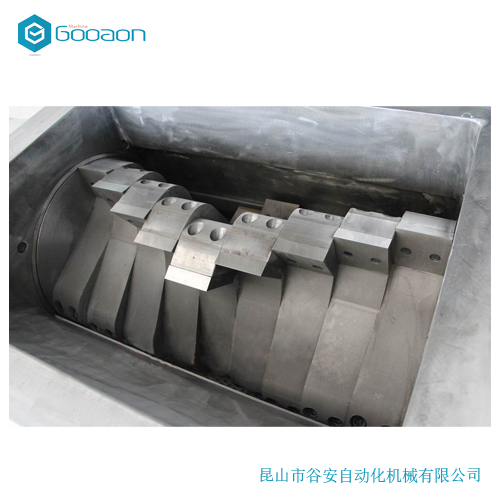

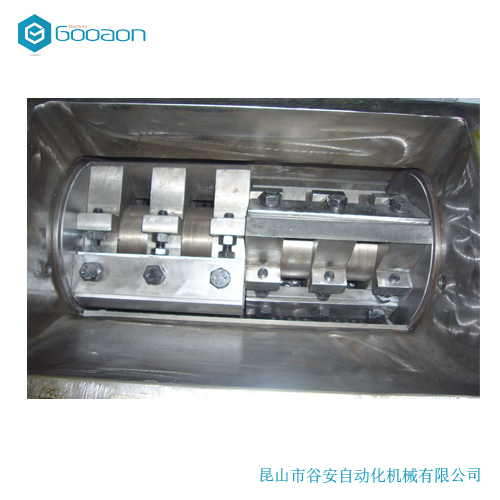

3. Unique tool holder design and high-quality tool (tool material SKH-2) are prepared, so the particles of the crushed material are uniform and the powder is less.

4. The appearance size of the product is optimized to the minimum, which saves the space, and the bottom is equipped with pulleys, which is convenient to move.

5. Wide range of uses: This model is used for crushing and recycling soft and hard materials such as PU, PET, PC, ABS and other nozzle materials.

6. Easy-to-remove design, easy to change color and material, compact and occupy less space, suitable for use in small workshop machine room.

7. It is equipped with protection systems such as motor overload, power supply chain and safety switch, and a card machine alarm system, which is convenient and safe to operate.

8. There are hopper type and automatic recovery type to choose from. Hopper type, with a hopper under the machine to load the crushed materials; automatic recovery type, the machine has a matching recovery system, which can directly recycle the crushed materials and feed them into the injection molding machine for continuous recycling.

The difference between a slow silent pulverizer and a powerful pulverizer

Advantages and disadvantages of powerful crusher:

The speed of the cutter shaft is fast, and the impact crushing and the cutting and crushing of the cutter have a good crushing effect on most plastics, rubbers, Chinese herbal medicines, and wood-plastic products. And the crushing power has a wide selection range from small to large. The small machine can be used for machine-side crushing and an immediate recovery device can be installed to save manpower, material resources and turnaround time. The large-scale machine can realize centralized crushing and high output. It can also be equipped with a large-scale recycling and bagging fan. At the same time, the crushed materials are blown into the storage bucket through the fan. Compared with the slow-speed pulverizer, the powerful pulverizer is noisy, and the pulverized materials are not as uniform as the slow-speed pulverizer.

Advantages and disadvantages of slow silent grinder:The speed is slow, the teeth are crushed, the particles are uniform, there is no screen, and the disassembly and cleaning are convenient. The noise is small, and the noise value is about 20DB when idling. Most of them are used for machine-side pulverization. Compared with powerful pulverizers, slow pulverizers are only suitable for the pulverization of hard plastics, and the pulverizing power is relatively small and the cost is relatively high.