。

Nitrile Butadiene Rubber Crusher, Styrene Butadiene Rubber Crusher, Bulk Rubber Crusher

一、Rubber crushing characteristics

We call elastic soft rubber. Such as mainly refers to nitrile, styrene-butadiene, EPDM, cis-butadiene, TPU, PE and other large rubber materials, due to its soft, elastic and low temperature resistance, it will be damaged during the crushing process. The following problem occurs:

1. The elasticity is large, and it cannot be broken by impact alone.

2. The fluidity is not strong, the cutting is not smooth,

3. The material is heated up by repeated friction in the crushing chamber

4. In case of heat, it will clump together and cannot be used.

5. Glue on the cutter and screen.

二、properties of rubber

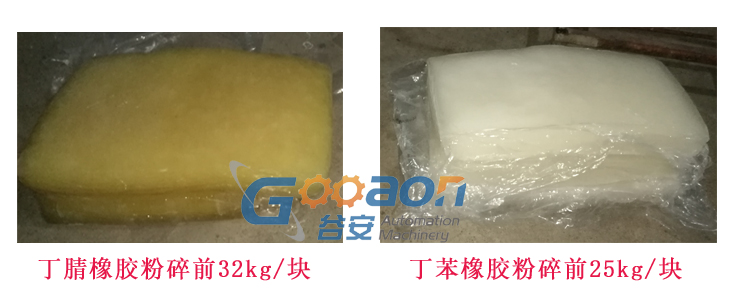

Nitrile rubber is obtained by emulsion polymerization of butadiene and acrylonitrile, called butadiene-acrylonitrile rubber, referred to as nitrile rubber. Nitrile rubber is mainly produced by low temperature emulsion polymerization, which has excellent oil resistance, high wear resistance, good heat resistance and strong adhesion.

Nitrile-butadiene rubber is a light yellow to tan elastomer with a slight underarm odor. Its density varies with the increase of acrylonitrile content. It is soluble in benzene, toluene, esters, chloroform and other aromatic hydrocarbons and polar agents.

The disadvantages are poor low temperature resistance, poor ozone resistance, poor electrical properties and slightly lower elasticity. Nitrile rubber is known for its excellent oil resistance and is widely used in the rubber industry.

Due to its high thermal and viscous properties, it has high requirements for the crushing process, and ordinary crushers cannot achieve the effect. Gu'an Machinery specially developed a nitrile rubber crusher with excellent performance.

Common natural rubbers include nitrile rubber, butadiene rubber, styrene butadiene rubber, butyl rubber, neoprene rubber, isoprene rubber, ethylene propylene rubber, etc.

三、Product features:

1. Two kinds of steel with different properties are used for the tool material: high-hardness high-speed steel is used for the cutting edge part, which greatly improves the cutting and crushing ability of the cutting edge (higher hardness than SKD-11 material). The cutting is completed at one time, decisively without sidebands .At the same time of high cutting cutting, it avoids multiple cutting and friction caused by one-time cutting not in place.

2. The knife body is made of steel with low hardness, which enhances its toughness, greatly improves the impact resistance of the knife, and ensures the crushing force of bulk materials.

3. The crushing chamber adopts a low-temperature design, so that the material can be crushed in a low temperature environment of 5-20 degrees, so as to avoid the melting of the material due to the temperature rise. smooth.

四、Product Features:

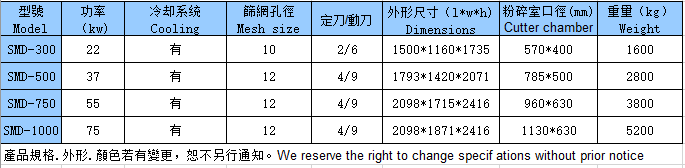

五、technical parameter:

Business hotline: Miss Liu 13776319563

Technical support: Gu Gong 18913224469

e-mail address:gooaon@163.com

Ali Wangpu:https://www.gooaon.com.cn

Address: No. 56, Gangpu East Road, Zhangpu Town, Kunshan City, Suzhou, Jiangsu Province

Product selection

technical support