。

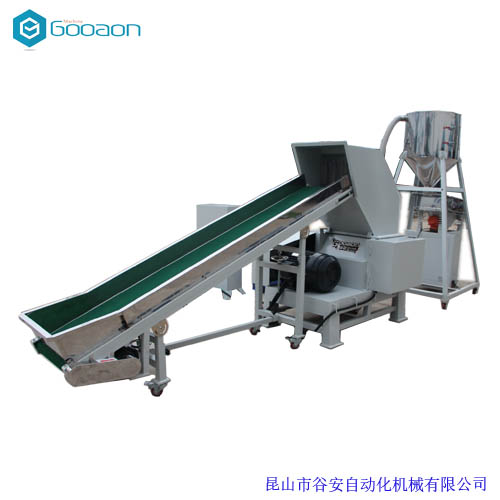

Tire Inner Tube Shredder | Tire Inner Tube Shredder | Inner Tire Shredder This is a complete set of equipment, from feeding, to crushing particles, to conveying and classifying them into different particle sizes, and making waste rubber tires into particles. It can directly pulverize waste car tires, rubber waste, colored rubber sheets, vulcanized rubber sheets, etc. into small particles of 0.5~6MM, and the pulverized particles can be made into colored floor tiles, composite floors, anti-static floors, etc. Large-scale application In swimming factory hall, kitchen, bathroom, computer control center room, playground runway, court, playground ground.

Tire Tube Shredder | Tire Tube Shredder | Inner Tire Shredder

This equipment is mainly used to smash tire inner tubes. The main characteristics of tire inner tubes are that they have strong elasticity and no steel wires, which are suitable for this recycling and shredding line.

Product overview

The pulverizer is mainly used for the pulverization of waste automobile tires, silica gel, PU rubber material and rubber vulcanized sheet. These materials can be pulverized into fine particles of 0.5-5mm, and they can be screened by a screening machine and can be sieved into 0.5-1mm according to requirements. , 1-2mm, 2-3mm, 3-4mm, 4-5mm and other different sizes, crushing and screening work can be completed automatically by the production line. It can be made into colored floor tiles, composite floors, anti-static floors, and is widely used in swimming pools, computer control centers, playground runways, courts, and swimming grounds.

The crushing of tire inner tube material has certain particularities:

1. High tensile strength about 4.5MPa

2. The hardness is about 65 degrees lower

3. Has about 30% elasticity

4. The rubber contains calcium carbonate after vulcanization, which has strong wear resistance

The rubber recycling industry is an emerging industry formed in recent years, mainly recycling waste automobile tires and waste rubber materials.

Grinding rubber into powder can be made into rubberized asphalt membranes and waterproof materials; adding rubber powder to high-speed road surfaces reduces costs and increases service life; motor vehicle brake pads, sound insulation materials, sealing strips and other products are also mixed with Incorporates rubber powder; rubber powder can also be used in the coating industry.

Pulverize the rubber into uniform particles, and can also be made into ground paving materials, or made into colored floor tiles, composite floors, anti-static floors, etc. , playground floor

Gu'an Rubber Particle Pulverizer is specially designed for the rubber recycling industry. It can directly pulverize waste automobile tires, rubber waste, color rubber sheets, vulcanized rubber sheets, etc. Grading according to different particle sizes, and then bagging. It can realize crushing, crushing, sorting, and bagging at one time, with less labor input, 1 to 2 people can operate the whole set of equipment, and the output per hour is 300KG--600KG.

This set of models can work continuously for 24 hours. The machine itself has a cooling system, which can effectively reduce the working temperature of the machine body, and control the temperature of the rubber material during the crushing process, so as to improve the crushing efficiency. The entire crushing, conveying, and sorting process are all airtight. Completed, there will be no dust overflow, no pollution to the environment, and at the same time keep the rubber particles clean.

This set of models is equipped with screens with different apertures to choose from, which is suitable for the needs of different molding particle sizes. When changing colors, you only need to use an air gun to blow clean the inside of the machine, which is convenient and quick to clean and maintain. Centralized control system, the whole set of equipment A control cabinet, complete fault warning and protection devices, easy to operate and easy to understand.

Features:

▪ Double-layer feeding hopper, filled with sound insulation material, effectively reducing working noise;

▪ The grinding chamber is fully polished and ground, and the thickened steel plate is welded as a whole, with good precision;

▪ The tool holder is processed by wire cutting to ensure the accuracy, perfectly matched with the central axis, and the assembly is clean and neat;

▪ The central axis and the tool rest are assembled by hydraulic pressure, without any solder joints and materials, which is convenient for cleaning and avoids deformation due to welding;

▪ The top knife block and the knife holder are cut from the same thick steel plate, which is beautiful and elegant, will not shift or fall off over the years, and avoid welding slag accumulation;

▪ The knives are made of imported alloy steel. According to the characteristics of different materials, SKD-11 or SKH2 are selected. The perfect material ensures excellent quality;

▪ SMD-150 and above, equipped with crushing chamber cooling water device, which can effectively reduce the working temperature of the crushing chamber and avoid material agglomeration;

▪ Protection function: motor overload protection, limit switch protection, etc.

Tire Tube Shredder | Tire Tube Shredder | Inner Tire Shredder

Product parameters

Business hotline: Miss Liu 13776319563

Technical support: Gu Gong 18913224469

e-mail address:gooaon@163.com

Ali Wangpu:https://www.gooaon.com.cn

Address: No. 56, Gangpu East Road, Zhangpu Town, Kunshan City, Suzhou, Jiangsu Province

Product selection

technical support