。

PET Preform System

PET Preform System

In the PET preform system process, drying becomes a particularly critical stage, and it must be ensured that the moisture in the raw materials is removed and the drying temperature is reasonable. Gu'an's dehumidifying dryer can provide dry air with a dew point of -40°C or lower, and can monitor various parameters in a timely manner and ensure a constant dew point.

The parts in contact with the raw materials are made of stainless steel and the filter device of the conveying system effectively ensures that the PET raw materials are not polluted during the conveying process. The flexible conveying air supply adjustment system, by adjusting the conveying speed, effectively avoids the situation of drawing or dusting PET raw materials due to different conveying conditions.

For the conveying system of PET high-temperature raw materials, Shini has specially designed a solution with water cooling function, which reduces the risk of conveying high-temperature raw materials by the suction machine.

The closed cycle secondary conveying system can greatly reduce the heat loss during the conveying process and the risk of re-absorbing moisture of the dried raw materials during the conveying process of the hot material and the heat preservation hopper that needs to be sent to the molding machine after drying.

Color matching system

Guan volume color masterbatch machine can be used for metering of crystalline and amorphous color masterbatch raw materials, the production range is 0.2~32kg/hr. If the customer has higher requirements for the addition ratio and accuracy of the color masterbatch, we recommend the use of a weightless color masterbatch machine, which adopts the weightless measurement method, and the production range is 0.04~32kg/hr. The internal cooling water circulation cooling function prevents the color masterbatch pellets from entering the possible melting of the PET main material, thus ensuring accurate metering. Several mold cycles can be set to add color masterbatch once to meet the requirements of micro-measurement.

Weighing mixer

The special high temperature weighing type mixing mixer design, including the weighing sensor and the material level detector, can deal with the high temperature raw material processing of PET crystallization. The controller is equipped with an Ethernet interface, and with the corresponding software, the raw material proportioning data (such as maximum output, actual output, and proportioning accuracy) can be read through this communication interface to facilitate product quality control. The automatic repeat calibration function will automatically calibrate the program after each load to ensure the best proportioning accuracy. It has the function of automatic compensation for recycled materials, which can automatically calculate the color difference compensation according to the amount of recycled materials. In order to meet the measurement of recycled sheets, a special broken bridge structure and cutting method are adopted to ensure the continuity of the whole system.

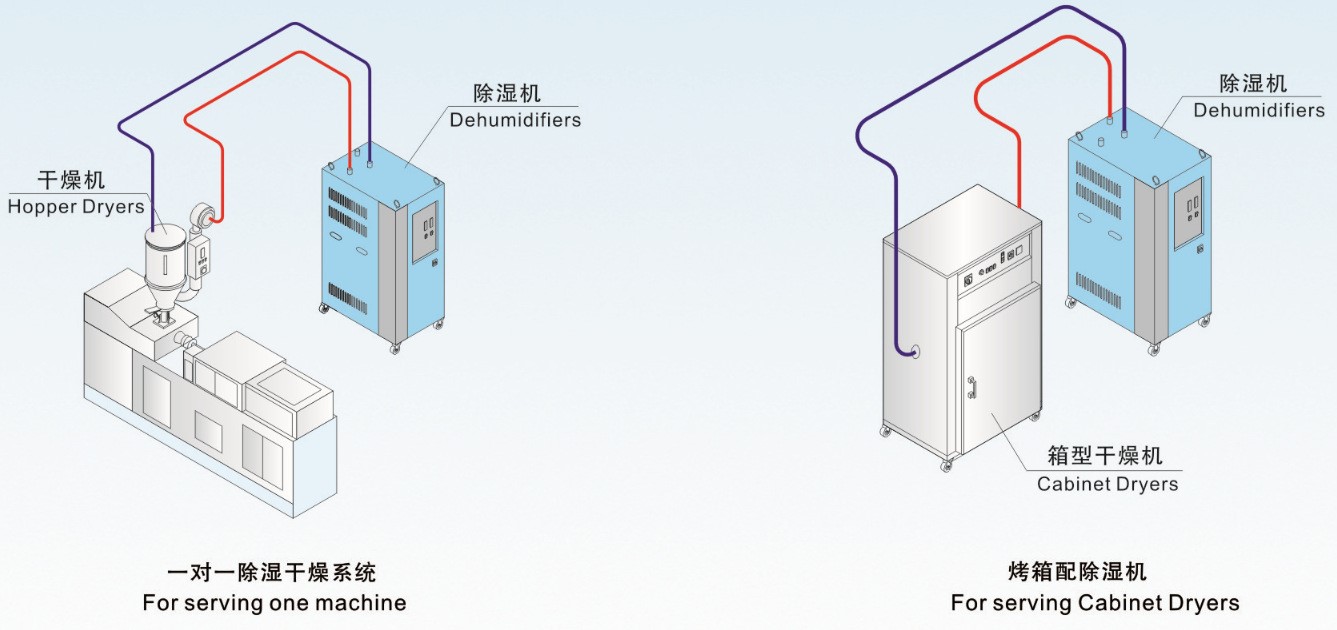

Dehumidification and drying system

In the PET preform system process, drying becomes a particularly critical stage, and it must be ensured that the moisture in the raw materials is removed and the drying temperature is reasonable. Gu'an's dehumidifying dryer can provide dry air with a dew point of -40°C or lower, and can monitor various parameters in a timely manner and ensure a constant dew point. Dew point setting and intelligent regeneration function, the dew point temperature of traditional dehumidifiers cannot be set, and dehumidifiers are working at the maximum load state. However, when processing PET raw materials with high humidity requirements, the dew point must be set and controlled. The setting of dew point temperature is related to the control of regenerative energy, which reduces energy consumption compared to traditional dehumidifiers.

PET crystallizer

Gu'an PET crystallizer is specially designed to overcome the glass transition temperature of raw materials and ensure homogeneous crystallization, avoiding the phenomenon of bonding or bridging of raw materials. Models of this series range from 100KG to 1500KG. The material level detection system can adjust the operation mode of the crystallizer and the feeding device according to the actual raw material amount detected by the material level meter. The precise temperature sensing control system is adopted, and the discharge port is equipped with a rotary blanking valve to achieve continuous crystallization and prevent degradation.

Mold dehumidification system

Dew condensation occurs when the surface temperature of the mold is lower than the dew point temperature of the surrounding air, and moisture will be generated, which will affect product quality and production efficiency, and will corrode the mold surface, thereby causing environmental pollution. Gu'an mold dehumidifier can effectively solve the problem of condensed water formed in the mold shell and cavity due to the use of chilled water in the mold to shorten the molding cycle, ensuring stable molding conditions and the maximum production capacity of the PET system.

cooling system

Gu'an's chiller cooling system can accurately control temperature, flow and pressure to maximize the cooling effect. Its products include air-cooled and water-cooled chillers, cooling towers, pumps, and water tanks. On the basis of standard equipment technology, Guan can provide customers with personalized solutions to meet different needs. The frequency conversion control chiller, the frequency conversion compressor can be used for frequency conversion according to the change of load, adjust the cooling capacity of the machine to make the chilled water temperature constant, achieve the purpose of precise temperature control, and save 15% energy compared with the traditional chiller.

PET moisture content online detection

In PET molding production, the level of moisture content is the most critical acceptance criterion for preform producers. In order to ensure the high quality of the product, the moisture content of the PET raw material before molding must be controlled within the acceptable range. The moisture content tester is specially used for the detection of the moisture content of the PET raw material.

Business hotline: Miss Liu 13776319563

Technical support: Gu Gong 18913224469

e-mail address:gooaon@163.com

Ali Wangpu:https://www.gooaon.com.cn

Address: No. 56, Gangpu East Road, Zhangpu Town, Kunshan City, Suzhou, Jiangsu Province

Product selection

technical support