。

Metal Separator | Plastic Particle Metal Separator | Pipeline Metal Separator

Metal Separator | Plastic Particle Metal Separator | Pipeline Metal Separator

一、Product overview

Metal separators use the principle of electromagnetic induction to detect metals. All metals including ferrous and non-ferrous have high detection sensitivity.

The entry of ferromagnetic metals into the detection area will affect the distribution of magnetic field lines in the detection area, thereby affecting the magnetic flux in a fixed range.

When non-ferromagnetic metals enter the detection area, the eddy current effect will occur, and the magnetic field distribution in the detection area will also change.

It is mainly used to detect loose granular materials (particles <8mm) fed by gravity flow, and can be used in the plastics industry, food industry, chemical industry, etc.

Harm of metal impurities in product molding:

1. Injection molding: damage the screw, scratch the cylinder, block the nozzle.

2. Mold aspects: scratch the mold. Block the mold runner.

3. Product: The finished product contains metal, which leads to short circuit and non-insulation, and scratches the surface of the product.

4. In terms of crushing processing: damage the crushing blade, resulting in more metal fragments.

二、The principle of the product

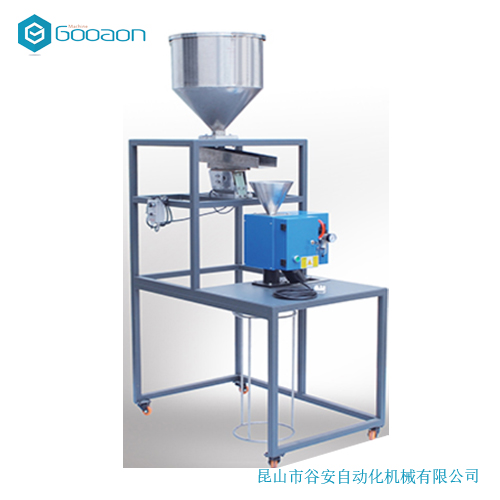

Usually the metal separator consists of two parts, namely the metal separator and the automatic rejection device, of which the detector is the core part.

Three sets of coils are distributed inside the detector, namely the central transmitting coil and two equal receiving coils. The oscillator connected to the middle transmitting coil generates a high-frequency variable magnetic field. In the idle state, the induced voltage of the receiving coils on both sides is generated. Before the magnetic field is disturbed, they cancel each other out and reach an equilibrium state. Once the metal impurities enter the magnetic field area and the magnetic field is disturbed, this balance is broken, and the induced voltages of the two receiving coils cannot be canceled. ).

The system can use the alarm signal to drive the automatic removal device, etc., so as to remove the metal impurities from the production line.

三、Product Features:

1. Magnetic and non-magnetic metals can be detected and separated to avoid the impact of metals on production equipment and product quality in the subsequent production process.

2. It can effectively solve the problem of non-ferrous metals (such as copper, stainless steel, lead, aluminum, etc.) that cannot be attracted by magnets.

3. It can be directly installed at the injection port of the injection molding equipment, or it can be used alone.

4. The special rejection structure can ensure the rapid and accurate separation of metal particles.

5. Widely used in plastics in free fall environment. food. Chemical industry and other industries.

四、Product performance

1. Integrate detection coil, controller and separation device into one, easy to install and use;

2. Rapid rejection by the rejection device can minimize material loss;

3. Small installation height for easy integration;

4. Test material characteristics: dry, good fluidity, no long fibers, no electrical conductivity;

5. Detecting material temperature: less than 80℃, if the temperature exceeds this range, special high temperature options can be selected;

6. The controller can be installed at 10m from the detection position;

7. Protection class: IP65

五、Product parameters

六、Product mix plan

Business hotline: Miss Liu 13776319563

Technical support: Gu Gong 18913224469

e-mail address:gooaon@163.com

Ali Wangpu:https://www.gooaon.com.cn

Address: No. 56, Gangpu East Road, Zhangpu Town, Kunshan City, Suzhou, Jiangsu Province

Product selection

technical support