。

Runway pellet crusher, EPDM runway granule crushing line, TPU runway granule crushing

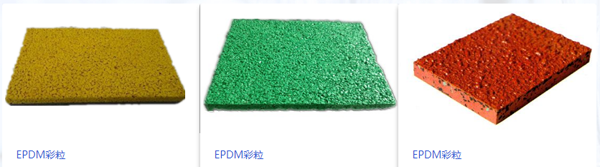

First, the characteristics of runway particles:

EPDM material has outstanding aging resistance, electrical insulation properties and ozone resistance. Excellent weather resistance, ozone resistance, heat resistance, acid and alkali resistance, water vapor resistance, color stability, electrical properties, oil filling and room temperature fluidity, and has good resistance to various polar chemicals such as alcohols, acids, alkalis, oxidants, refrigerants, detergents, animal and vegetable oils, ketones and greases;

However, it is less stable in lipid and aromatic solvents (such as gasoline, benzene, etc.) and mineral oils. Under the long-term action of concentrated acids, the performance should also reduce the water vapor resistance and be estimated to be better than its heat resistance. In superheated steam at 230 °C, there is no change in appearance after nearly 100 hours. Fluoroelastomers, silicone rubbers, fluorosilicone rubbers, butyl rubbers, nitrile rubbers, and natural rubbers experience obvious deterioration in appearance in a short period of time under the same conditions.

Due to the non-polar substituents in the molecular structure of ethylene propylene rubber, the molecular cohesion energy is low, and the molecular chain can maintain suppleness over a wide range, second only to natural rubber and butadiene rubber, and can still be maintained at low temperatures. Due to the lack of active groups in the molecular structure, the cohesion of EPDM rubber is low, and the rubber compound is easy to spray frost, and the self-adhesive and mutual adhesion are very poor.

Second, the characteristics of the composite spray particle plastic runway

Composite spray particle plastic runway Because the surface wear-resistant layer is the use of EPDM rubber particles and surface polyurethane mixed slurry after fully stirring sprayed on the composite elastic layer, its EPDM rubber particles are wrapped in the surface layer of polyurethane mixed slurry, so the spray particles compared with the traditional sprinkler particles its solid particle performance is much higher than the traditional plastic runway. The bonding of the polyurethane elastic layer is the same kind of performance product in terms of physical properties, so it is not easy to cause threshing when using, and cleaning the plastic runway surface is also easier and more convenient than that of the traditional plastic runway.

Hybrid traditional plastic runway is not affected by climate and other conditions, high strength, high wear resistance, flat and uniform site, can absorb vibration, shockproof sound insulation, bounce freely, anti-slip, good elasticity, low temperature resistance, site hardness adjustment appropriately. Because the venue is bright and beautiful, it gives the sports field a sense of comfort and excitement, which helps athletes to play or improve their performance.

Runway pellet crusher, EPDM runway granule crushing line, TPU runway granule crushing

Third, the description of the product

Runway granules for the size of the material particles, output, the aesthetics after crushing have strict requirements, especially for the change of material characteristics is the most important, ordinary blade knife or claw knife crusher crushing, will change the elasticity of the material, resulting in the production of the runway, security inspection unqualified. For this reason, Guan Machinery specially designed a special tool and tool holder structure, the color particles crushed out are both beautiful and do not change the material characteristics. It is a new upgrade product and is widely loved by users.

Fourth, the design principle

Runway material, its appearance has high requirements, mainly required its high aesthetics, so some customers require it to have edges and angles, some require its roundness, can not be which, the size of the particles have strict requirements, the same batch of particle size to be consistent,

So the Gu'an runway particle crusher first crushes out beautiful particles, and then screens the consistent particle size of the machine. Unique 5-claw knife holder design, the production capacity is 2 times that of the general ordinary shredder, and the special screening machine can meet the requirements of large-scale screening.

Runway pellet crusher, EPDM runway granule crushing line, TPU runway granule crushing

Fifth, the characteristics of the product

1. The tool adopts imported alloy tool steel, which is suitable for the characteristics of granular materials, durable and wear-resistant, and it is not easy to not be notched when cutting.

2. Clever cutting angle makes crushing more labor-saving

3. The components of this model have higher sealing to avoid wear caused by powder entering the mechanical running part

4. The place where the crusher is in contact with the material is made of wear-resistant materials

5. The chassis is designed with holes for powder discharge to avoid dust from entering the bearing

6. Gu'an runway granule crusher has good appearance sealing performance, which can effectively prevent dust leakage during crushing

7. Motor overload protection, cover opening power off protection and other protection functions; Can work continuously 24 hours a day

8. The operation and maintenance is simple, one on and one off two buttons to control

9. Easy-to-disassemble design, into the hopper, crushing knife, screen can be disassembled, easy to clean and change color

10. The knife holder adopts wire cutting processing to ensure accuracy, perfect coordination with the central shaft, and clean assembly

11. The central shaft and the tool holder are formed by hydraulic assembly, without any solder joints, without hiding materials, which is conducive to cleaning, and avoids deformation of the central shaft due to sintering

12. The top knife block and the knife holder are cut from the same thick steel plate, which is beautiful and generous, and will not shift or fall off over the years, while avoiding welding slag storage

Sixth, technical parameters

Senven. Picture display

Business hotline: Miss Liu 13776319563

Technical support: Gu Gong 18913224469

e-mail address:gooaon@163.com

Ali Wangpu:https://www.gooaon.com.cn

Address: No. 56, Gangpu East Road, Zhangpu Town, Kunshan City, Suzhou, Jiangsu Province

Product selection

technical support